The service hotline:

0739-5051798 13975998481

Product center

产品中心

Product details

Current location:Home Page > Product center > Product details

Hemispherical hydraulic control valve (fully automatic hydraulic hemispherical butterfly valve)

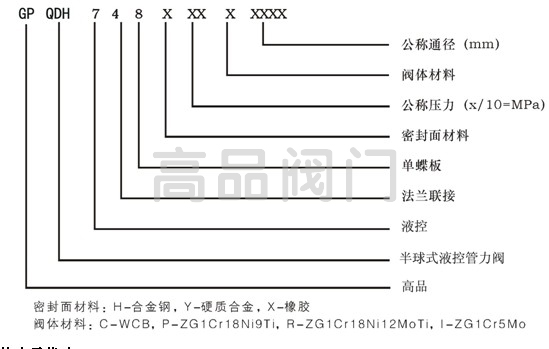

Mobel:GPQDH748-P

1. background of technology development

Centrifugal and mixed flow liquid pumps start a large starting current in the motor, so it is easy to burn the motor. In the past, large resistance stacks and frequency converters were used to reduce current. They had large investment, large space occupation and large energy loss. Centrifugal, mixed flow and axial liquid pump in the stop pump, because the backwater will produce a huge impact water hammer, the destruction of the pump body, the bottom valve, resulting in the entire system failure. Therefore, it is very necessary to replace a buck starting device with a valve, and eliminate new valves of water hammer, check valve or bottom valve.

At present, domestic and foreign pump outlet valves are mainly: stop valve type pump control valve (multi-function pump control valve), hydraulic driven butterfly valve (hydraulic control butterfly valve). Because of the big resistance coefficient (1.5 ~ 2.2) and large caliber (especially DN1000mm) valve, the cut-off valve type pump control valve has a huge space, difficult to overcome in manufacturing and installation. The hydraulic driven butterfly valve is complicated and difficult to debug and maintain because of the existence of electricity and oil pressure system. The hidden danger of oil spill and so on can not be overcome. Therefore, according to the actual working conditions, our company has developed a new generation pump outlet valve, hemispherical liquid control valve, on the basis of the advantages of digestion and absorption of micro resistance and closed check valve, liquid controlled butterfly valve, multi-function pump control valve, hemisphere valve, three eccentric butterfly valve, wedge valve and cut-off valve. Patent number: ZL02802933.X)

2. functions and uses

The hemispherical liquid control valve is installed at the outlet of the water pump. It is mainly used in the transportation of water supply and drainage system in power, municipal, iron and steel, coking, petrochemical, chemical, waterworks, light textile, food processing and other industries. With the function of cut-off valve, hemispherical valve, butterfly valve, check valve and water hammer eliminator, it can effectively improve the safety and reliability of the system and meet the automatic control requirements of the outlet fluid of the pump when it is open and stop. Because the occupying space is relatively small, it is especially suitable for large diameter (DN1000mm) pipeline system.

Two. The main features and advantages

1. the working force is taken from the medium of the valve and no external power source is needed. When the pump stops and stops, the valve can act according to the running rule of the pump automatically. No manual, electric, pneumatic, hydraulic and other external forces are required. Manual operation is not required. It has the effect of automatic slow opening, quick closing and slow closing. The operation is safe and reliable.

The 2. flow area is large and the cross section area of the valve plate is small. It is 80% less than the ordinary pump control valve, and the energy saving effect is obvious. The resistance coefficient of this valve is 0.5-0.8.

3. the valve plate is streamlined. If the fluid is laminar flow when entering the valve, the fluid can still maintain laminar flow when the valve is discharged, so it can be applied to some specific working conditions.

4. valve body sealing surface is a conical surface and the sealing surface of the valve plate is spherical. It is made of high hard material. It can cut off, crush and drain all kinds of filamentous, granular suspension and semi suspended impurities. The other characteristic of the eccentric sphere is automatic compensation for wear, especially ball depression.

5. sealing area is very small, full use of the full energy of the medium in the valve to push the valve plate seal, the sealing energy is huge, so the seal specific pressure is especially huge, so that the zero and hard seal can be realized smoothly.

6. valve body body structure adopts eccentric butterfly valve type, the flow line tortoise back valve plate structure can withstand high pressure and can make the wall thickness to the lowest, thus overcoming the disadvantage of the butterfly valve high pressure, and greatly extends its pressure range; the shape and rotation track of the valve plate seal face, such as the hemispherical valve, form a line seal, but overcoming the hemispherical valve occupying air. The smaller the sealing surface of the seal surface is, the smaller the clearance area of the valve plate is, the smaller the closed area of the valve plate is, the larger the area is, the larger the wedge valve is, it also overcomes the disadvantages of the large space and the large wear of the seal face, and the closing time and the initial time of the opening of the valve reclose the axis of the valve, such as the cut-off. The valve's switch movement, but overcoming the shortcoming of the shut-off valve and the huge switching force, this valve combines all the advantages of the three eccentric high hard seal butterfly valve, the hemisphere valve, the wedge valve and the cut-off valve, and discard all the defects.

7. can be used for centrifugal pumps, mixed flow pumps, or axial flow pumps.

8. the occupying space is relatively small, especially suitable for large diameter pipelines (DN1000mm or above).

9. the structure is simple and reasonable, easy to install and debug, and has a large service life.

Five. Technical parameters

Nominal diameter: DN 200~4000mm nominal pressure: 1, 1.6, 2.5, 4.0MPa

Minimum action pressure: 0.05MPa applicable temperature: -10~200 C

Applicable medium: water hammer, gas, oil, chemical fluid and other water hammer peaks: 1.3 times the working pressure of the pump.

Slow closing time: adjustment time in 1~120S: 6~120S adjustment

Resistance coefficient: less than 0.5

Sealing performance: working pressure 1.1 times, duration 15S, leakage 0.01%XDN "GB" below.

Six. The material of the main parts

Body: carbon steel, stainless steel pressure cylinder: carbon steel, stainless steel.

Valve plate: carbon steel, stainless steel and stem: stainless steel.

Sealing surface: alloy steel, cemented carbide and O ring: natural rubber, butadiene rubber, silicone rubber and fluorine rubber.

Seven. Comparison of the valve and other pump control valves

Other pump control valves are mainly cut-off valve type pump control valve (divided piston type and diaphragm type, control power from piston cylinder or diaphragm cylinder, attributable to the same structural principle) and hydraulic driven butterfly valves (storage energy and heavy hammer type), storage type is to overcome the fluctuation of liquid pressure, heavy hammer is the use of gravity as auxiliary. The principle is the same as those of the same type. Therefore, the comparison between the valve and the globe valve control valve and the hydraulic driven butterfly valve is only listed. (see the appendix)

|

Hemispherical liquid control valve

|

Cut-off valve type pump control valve

|

Hydraulic driven butterfly valve

|

|

No external power

|

No external power

|

External power

|

| Apply to centrifugal pump, mixed flow pump, axial flow pump | Can only be used for centrifugal pumps and mixed flow pumps | Apply to centrifugal pump, mixed flow pump, axial flow pump |

| The flow surface is the same as the pipe diameter, the valve plate is streamlined and the resistance coefficient is small (0.4~0.5). | When the medium passes through several curves, the resistance loss is very large along the way, and the drag coefficient is large (1.5~2.2). | The flow surface is the same as the pipe diameter. The back surface of the valve plate is complex and the resistance coefficient is small (0.6~0.8). |

|

Non electric cabinet

|

Non electric cabinet

|

The electric charge cabinet must be required

|

|

Small size of the same path and less investment in infrastructure

|

The same path is big, the investment of infrastructure is big

|

The same path is occupied by the air, and the investment in infrastructure is medium |

|

It is easy to find fault, easy to repair and easy to repair

|

It is easy to find fault, easy to repair and easy to repair

|

It is difficult to find fault, complicated maintenance and large amount of work |

| There is no need to operate at work, and everything is automatically carried out after pre adjustment. | There is no need to operate at work, and everything is automatically carried out after pre adjustment. | It must be operated at work. After pre adjustment, the hydraulic pump must be started, the hydraulic line valve should be opened, and the control power should be switched on. |

|

Keep laminar flow

|

Turbulence

|

Semi turbulent flow

|

| The length of the structure is short, and it can produce large diameter. At present, the production path has reached DN8000mm | The length of the structure is 2 times longer, the height is 2 times of the left valve of the same diameter, and it is very difficult to produce more than DN1000mm diameter. | The structure is of medium length (though it is a butterfly valve type), but to maintain gravity direction, the length of the structure is longer, and it can produce DN5300mm at present. |

| Suitable for wide range of pressure, and can produce more than 20MPa varieties. | Suitable for wide range of pressure, and can produce more than 20MPa varieties. | Applicable pressure range is limited, can not produce more than 20MPa varieties. |

| The sealing surface is high hard seal, anti-oxidation corrosion, anti liquid medium erosion and pressure fluid cavitation. | The sealing surface is rubber soft seal (some propaganda is soft and hard seal, and the actual sealing surface is embedded with a O ring. It is not as good as pure soft seal, and it has been worn out for several times. Anti cavitation | Sealing surface is high hard seal, anti-oxidation corrosion, liquid medium scour and pressure fluid exist cavitation, sealing surface material and valve body, valve plate material thermal expansion coefficient is very different, easy to crack |

| The combination of high hard sphere and conical surface can cut, crush, and arrange filamentous, granular suspended and semi suspended impurities to ensure reliable sealing. | Flat soft seal, filamentous, granular impurities remain on the sealing surface, easy to leak. | The sealing face is superimposed with angle. If filamentous and granular impurities are attached to the sealing surface, the valve can not be opened when it is closed, and the valve can not be closed when it is opened. |

| Making full use of the huge energy in the valve medium, the sealing area is small and the seal ratio is huge. | The area of the piston and diaphragm cylinder is fixed, the sealing area coincides with the area, and the sealing pressure is relatively small. | The total amount of external power is limited, the sealing area coincides with the area, and the sealing pressure is relatively small. |

| It has all the functions of 7 kinds of equipment, such as light load starter, hammer, check valve, butterfly valve, hemispherical valve, wedge valve, cut-off valve and so on, and avoid all the disadvantages of all these equipment. | It has all the functions of 4 kinds of equipment, such as light load starter, hammer hammer, check valve, globe valve and so on, and has all shortcomings of the globe valve. | The full functions of 4 kinds of equipment, such as light load starter, elimination hammer, check valve, butterfly valve, etc., have less advantages than butterfly valves, and other disadvantages of butterfly valves. |

| The sealing surface wear can be automatically shifted to compensate for zero leakage. |

No compensation, leakage of the seal surface after wear

|

No compensation, leakage of the seal surface after wear

|

Structure principle

Structural principle this valve is butterfly valve centrifugal pump, axial flow pump and mixed flow pump outlet control valve. When the pump starts, the pressure water passes through the channel, acting on the valve plate to produce thrust, but the valve plate is pressed and closed through the relay, the force transmission and the valve stem; the other way through the side tube slowly opens the pressure cylinder piston, so that the pressure cylinder, the relay, the force transmission, the valve stem and the valve plate rotate slowly, the valve plate opens, and reduces. The start load of the pump.

When the centrifugal pump stops running, under the action of backwater, the valve plate falls down to a certain angle quickly and leaves a certain gap to remove the water hammer. Under the action of the pressure water of the backwater pipe, the cylinder piston moves, and the pressure cylinder, the relay, the force transmission and the valve plate are turned off. The piston, the cylinder, the relay, and the power transmitter continue to move, tightly pressing the valve plate to prepare for the pump starting and reducing the load.

Contacts:Mr. Chen 13975998481

Company email:2323482529@qq.com

Company address:Shaoyang city double area industrial street river levee

Shaoyang Gaopin hydraulic valve Co., Ltd. all rights copyright

24 hour Hotline:

0739-5051798

business QQ:

2323482529