Gaopin quality comes from strict requirements for every production link

-

Quality

Ten years grinding sword One hundred high quality

We are a collection of scientific research, development, production and sales for the integration of science and technology enterprises, the company people-oriented, with senior technical titles of science and technology personnel of eight (including senior engineers, 2), intermediate technical title personnel 15 people, equipped with hydraulic valve research institute.

-

Design

Production conditions

To do a good job, must first sharpen his device. Covers an area of 40000 square meters, more than 360 employees, all kinds of professional and technical personnel more than 50 people. We have stronger valves, machinery products, such as the hydraulic system design and manufacture ability.

-

Testing

Scientific research and development

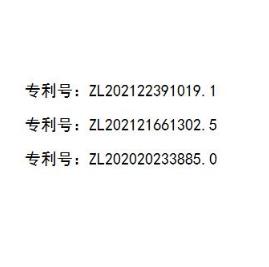

Innovation as the source, is the quality of life. Has successfully developed GPJH745X/P type automatic water pump control valve series, GPBH748H/Y type automatic hydraulic control hemisphere disc valve series of new products. The above products are has applied for national patent.

-

Quality

Marketing system

Customers as god, the promise is quality. 28 offices throughout the country, the products sell well all over the country, in the coking, metallurgy, petrochemical, chemical, electric power, mining, municipal and other industries have many excellent performance, has won praise users.